Simplifying your future

An Industrial Vision of Space Use Qualified Converters

Technical Article – Author: H. Huillet

Presentation:

PHASE 1 : Radiation hardened products

- Began working with CEA in 1995

- Project : 2KW 1Mrad power supply

- In parallel, experiments were conducted to evaluate standard hirel 4W modules behaviour under radiation

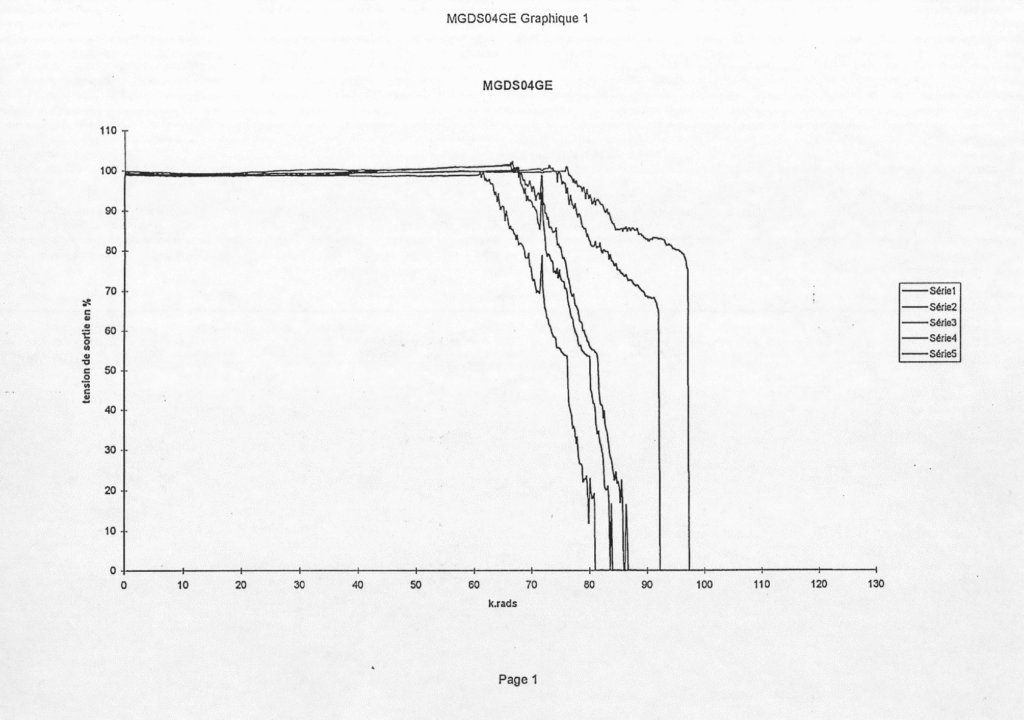

- Performance achieved : Up to 70KRad total dose

PHASE 2 : Standard Converters Qualification

- Beginning of cooperation with CNES in 1998

- Qualification of 4W and 10W converters for space use. Only potting compound was changed, No re-design

- Manufacturing based on the quality and industrial manufacturing structure of Gaïa – assembly of converters was done on the standard production lines

- Batch qualifications to ensure product consistency and performance

Results achieved :

- Life test : 1000 hours at 85°C, ON

- Thermal cycling : 300 cycles -40/+110°C, 10°C/min, 30 min dwell time

- Cumulated dose : 4.4 kRad @ 200 rad/h

- Damp heat : 85°C/85%RH, 500 Hours

- SEL SEE : Mosfet, op-amp, pwm

Currently, hundreds of converters delivered with units in operation on Rosetta, Deep Impact, microsat satellites like Demeter, Parasol, Essaim…

Limitations of this solution :

- Total dose behavior is very much batch dependent (from 4KRad to 70KRad), mainly related to the use of Bi-CMOS technology for the PWM

- Thermal dissipation not optimized for space use, difficult to evacuate heat by conduction, requires special mounting brackets…

PHASE 3 : Design of a space dedicated converter

2003 : Based on acquired background with CEA and CNES, it is decided to design a converter family (4W, 10W) for space use.

2 converters options were investigated from the technical and the industrial point of vue :

- Option 1 : 3D-stacking

- Option 2 : Open frame with optimal thermal design

Prototypes of 4W converters have been designed, with the following conclusions :

Advantages :

- Space qualified technology

- Space qualified production lines

- Ease of mounting, SMD package

- Prototypes of 4W con

Disadvantages and limitations :

- Commutation noise due to proximity effects (400mV

spikes) - Weight around 20gr for a 4W converter

- Thermal dissipation : only possible through board pins, hot spots can not be cooled efficiently. Due to this restriction, it is not possible to design high power converters.

- Potting causes important parameters variations – for example, inductance changes due to constraints

- Production line is not included in a large scale industrial production scheme that would generate cost savings, therefore it is expensive compared to COTS solutions

This approach was totally industry driven, using the same technologies that Gaia is using for its new standard product ranges :

- Designed according to

ESA-PSS-01-301 derating guidelines - Open frame converter, no potting

- Optimized thermal design, buried thermal drain in the PCB, heat dissipation possible by conduction through chassis mounting

- Bipolar technology

- Manufacturable on Gaïa standard production lines

SGDS04 and SGDS10 families Designed for space applications :

Components derating ESA-PSS-01-301

Dump input

Undervoltage lockout

Inhibition function

Synchronisation function

Adjustable output

Output regulation 0 to 100% load

Permanent output current limitation

Parallel operation (master slave)

Weight 8gr (4W), 10gr (10W)

Operating temperature range -40°c to

+85°c

Heavy ions and ionising dose 20Krad

characterised

Galvanic insulation 500 VDC

Integrated LC filter

EMI MIL-STD-461C with recommended

external filter

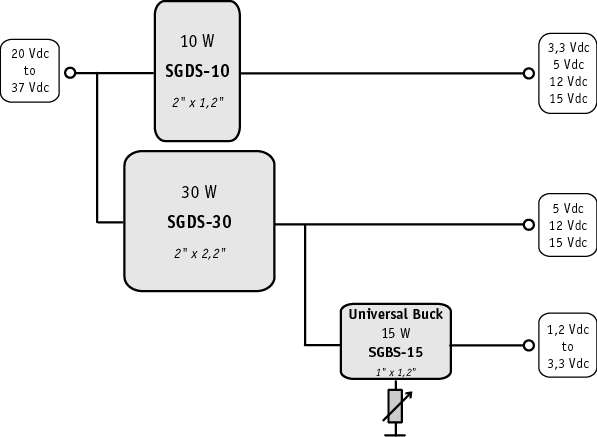

Space Architecture Modules

Advantages :

- Low output noise (60mV ripple + spikes)

- Due to bipolar technology, total dose caracterised to 20KRad

- No potting brings lightweight, higher reliability and higher consistency in production

- Simple assembly process, no mezzanine boards

- Possibility to design higher output power versions – no limitation due to the technology

- Manufactured on standard production lines used for other Gaia products leads to huge costs savings

Industrial approach : The assurance of space grade quality

- Design according to the ESA design rules

- Initial design validation :

- electrical, thermal, mechanical

- reliability (life-test, thermal cycling)

- radiations (heavy ions, total dose)

- Components production in consistent batches for a 3 year production

- approved suppliers

- radiation batch qualification

- drying of plastic case components and packing in dry pack

- nitrogen storage

- Purchasing of PCBs to approved suppliers (i.e. SYSTRONIC)

- Manufacturing of consistent batches :

- consistency of assembly through the use of automated assembly lines

- consistency of consumeables (solder pastes, glues…)

- Assembly by a qualified sub-contractor with periodic audits :

- Detailed flowcharts under control of Gaïa

- Re-inforced and monitored controls

- traceability and recording of all manufacturing operations

- Electrical tests with recording of results at -40/+85/+25°C

- Batch qualifications :

- life test 2000 h

- Thermal cycling : 500 cycles -40/+85°C

- DPA ( RX and visual inspections, micro-sections)

- Nitrogen storage of converters